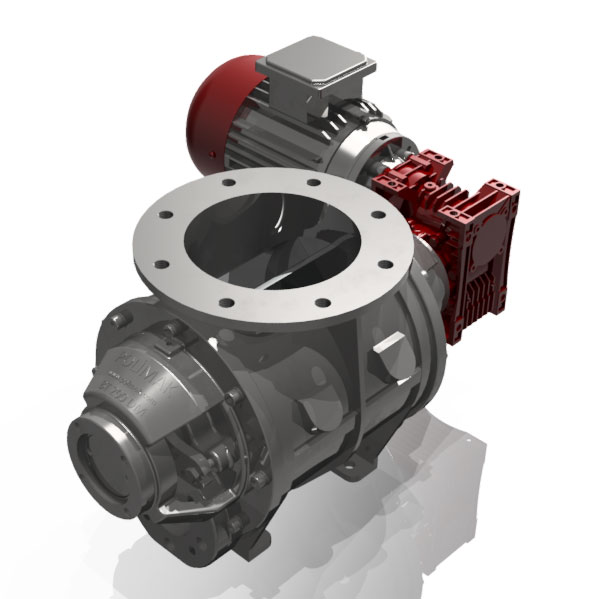

Unlike the drop-through valve, the blow-through valve has a sealed bottom. It does not contain an exit flange like that of the flow through valve, instead it has a trough where the pneumatic conveying line connects. The feed is supplied to the valve via the inlet port, then the rotor turns and drops the feed into the trough where it is blown out into the conveying line. It is suitable for more cohesive materials like flour, milk powder, custard etc.

Specifications

Housing:

Cast (GG25, SS304, SS316)

Weld (St37, St52, Hardox, SS304, SS316)

Rotor:

Cast (GG25, SS304 or SS316)

Weld (St37, St52, Hardox, SS304, SS316)

End plates:

Cast (GG25, SS304, SS316)

Weld (St37, St52, Hardox, SS304, SS316)

Seals: Lip seal, Gland packing.

Blow Through Capacity Table

|

Series |

Motor power(kw) |

Volumetric Capacity (liters/rev) |

Throughput (m3/hr.) |

|||||

|

10rpm |

20rpm |

30rpm |

40rpm |

50rpm |

60rpm |

|||

|

BT100 model |

0.11 – 0.25 |

0.4 |

0.24 |

0.48 |

0.72 |

0.96 |

1.2 |

1.44 |

|

BT125 model |

0.25 – 0.37 |

0.9 |

0.54 |

1.08 |

1.62 |

2.16 |

2.7 |

3.24 |

|

BT150 model |

0.25 – 0.55 |

1.8 |

1.08 |

2.16 |

3.24 |

4.32 |

5.4 |

6.48 |

|

BT200 model |

0.37 – 0.75 |

4.5 |

2.7 |

5.4 |

8.1 |

10.8 |

13.5 |

16.2 |

|

BT220 model |

0.37 – 0.75 |

5.7 |

3.42 |

6.84 |

10.26 |

13.68 |

17.1 |

20.52 |

|

BT250 model |

0.55 – 1.1 |

9.8 |

5.88 |

11.76 |

17.64 |

23.52 |

29.4 |

35.28 |

|

BT300 model |

0.75 – 1.5 |

17.3 |

10.38 |

20.76 |

31.14 |

41.52 |

51.9 |

62.28 |

|

BT350 model |

1.1 – 2.2 |

28.1 |

16.86 |

33.72 |

50.58 |

67.44 |

84.3 |

101.16 |

|

BT400 model |

1.5 – 3 |

42 |

25.2 |

50.4 |

75.6 |

100.8 |

126 |

151.2 |

|

BT450 model |

2.2 – 4 |

63 |

37.8 |

75.6 |

113.4 |

151.2 |

189 |

226.8 |

|

BT500 model |

3 – 5.5 |

86 |

51.6 |

103.2 |

154.8 |

206.4 |

258 |

309.6 |

|

BT600 model |

4 – 7.5 |

153 |

91.8 |

183.6 |

275.4 |

367.2 |

459 |

550.8 |

|

BT700 model |

5.5 – 11 |

222 |

133.2 |

266.4 |

399.6 |

532.8 |

666 |

799.2 |

|

BT800 model |

5.5 – 15 |

330 |

198 |

396 |

594 |

792 |

990 |

1188 |

|

BT900 model |

7.5 – 17.5 |

530 |

318 |

636 |

954 |

1272 |

1590 |

1908 |

|

BT1000 model |

7.5 – 22 |

663 |

397.8 |

795.6 |

1193.4 |

1519.2 |

1989 |

2386.8 |